RCC column footings are the crucial interface between a building’s vertical load-carrying system and the ground. A well-designed column footing ensures the safe transfer of loads, preventing excessive settlement and structural damage. This guide focuses specifically on designing these vital elements, providing a practical approach for structural engineers.

Types of RCC Column Footings:

The most common type you’ll encounter is the isolated footing, but understanding the alternatives is crucial:

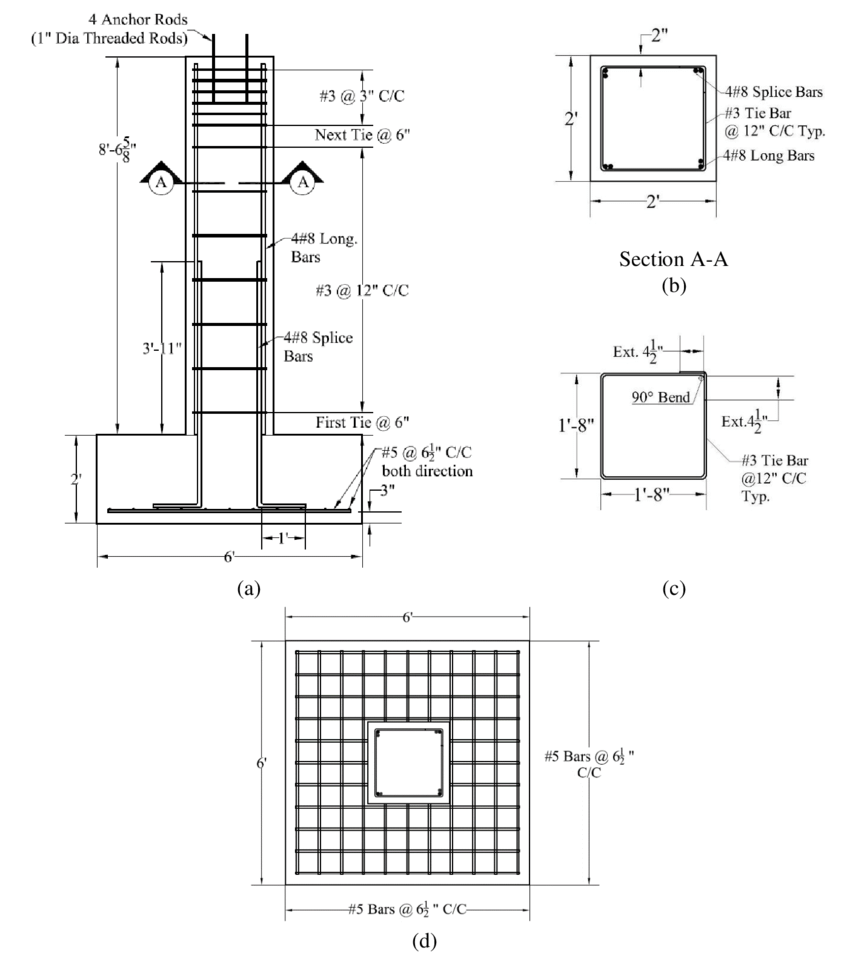

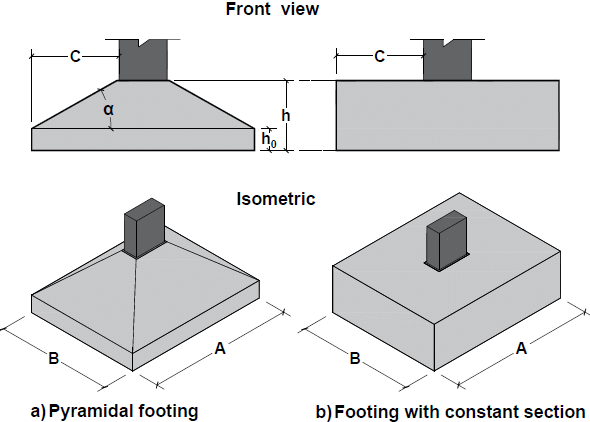

- Isolated Footings: Designed to support a single column. Typically square, rectangular, or circular. The focus of this post.

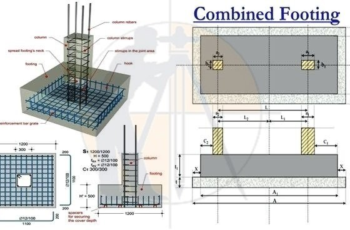

- Combined Footings: Support two or more columns, useful when columns are closely spaced or near a property line.

- Strip Footings: Continuous footings supporting a row of columns or a wall (less common for supporting primarily columns).

- Raft Foundations (Mat Foundations): A large, continuous slab supporting all or a significant portion of the building’s columns. Used for weak soils or heavy loads.

Key Design Considerations (Specifically for Columns):

- Soil Bearing Capacity (SBC): Absolutely critical. Derived from a geotechnical investigation report. The allowable SBC determines the footing’s size. Remember to apply appropriate factors of safety.

- Column Loads: Accurately determine the factored axial load (Pu) and moments (Mx, My) transmitted from the column to the footing. These loads are derived from structural analysis software, considering appropriate load combinations per your building code (ASCE 7, Eurocode, IS codes, etc.). Critical load combinations include dead + live, dead + wind, dead + live + seismic, etc.

- Footing Geometry and Size:

- Area Calculation: Required footing area (Af) = Pu / SBC.

- Shape Selection: Square footings are often the most economical. Rectangular footings are used when space is limited or when significant moments are present.

- Proportioning for Moments: If significant moments (Mx, My) exist, the footing should be proportioned to minimize eccentricity and prevent uplift.

- Footing Depth (Thickness): Determining the footing depth is an iterative process driven by bending, one-way shear, and two-way shear.

- Bending Moment: Calculate the factored bending moment (Mu) at the face of the column. The effective depth (d) is determined based on Mu, material properties (f’c, fy), and code-specified reinforcement ratios.

- One-Way Shear (Beam Shear): Check shear capacity at a distance ‘d’ from the face of the column. The critical section extends across the entire width of the footing.

- Two-Way Shear (Punching Shear): Check shear capacity at a distance d/2 from the face of the column. This is the most critical shear check.

- Development Length: Ensure sufficient development length for the column bars extending into the footing. Also, ensure adequate development length for the footing reinforcement.

- Minimum Cover: Provide adequate concrete cover as per the building code (typically 3 inches).

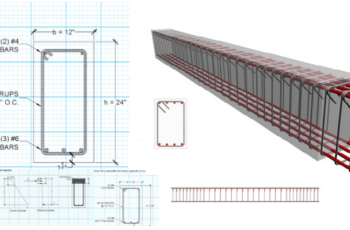

- Reinforcement Design:

- Area of Steel (As): Calculate the required area of steel reinforcement based on the factored bending moment (Mu) using appropriate design equations or moment-curvature analysis.

- Distribution: Distribute reinforcement uniformly across the footing width. Consider concentration of reinforcement near the column face if high moment gradients exist.

- Minimum Reinforcement: Meet minimum reinforcement requirements specified in your building code.

- Bar Spacing: Check that bar spacing meets maximum spacing limits to control cracking.

- Curtailment (Optional): In larger footings, you may consider curtailing some reinforcement bars away from the column face, based on bending moment diagrams. (less common and requires careful analysis).

- Transfer of Force at Column Base:

- Bearing on Concrete: Check the bearing stress on the concrete at the column-footing interface. If the bearing stress exceeds the allowable bearing capacity, provide dowels extending from the footing into the column to transfer the excess force.

- Dowel Design: Design dowels to transfer the remaining force (if any) from the column to the footing. Dowel bars must be adequately anchored in both the column and the footing.

- Code Minimum: Ensure the minimum number of dowels as required by your local building code (typically 4 bars).

- Settlement Analysis: While typically handled in the geotechnical report, consider the potential for differential settlement between column footings. Differential settlement can induce significant stresses in the superstructure. Consult with a geotechnical engineer if you have concerns.

- Code Compliance: Adherence to ACI 318 (US), Eurocode 2 (Europe), IS 456 (India), or the relevant local building code is mandatory.

Step-by-Step Design Process:

- Gather Information: Obtain the geotechnical report (SBC!), column loads (Pu, Mx, My), and relevant building code.

- Size the Footing: Calculate the required footing area based on Pu and SBC. Select a trial footing size (length and width).

- Determine Footing Depth:

- Assume a trial footing depth (h).

- Calculate the effective depth (d = h – cover – bar diameter/2).

- Calculate the factored bending moment (Mu) at the column face.

- Calculate the required area of steel (As) based on Mu.

- Check one-way shear and two-way shear. If shear capacity is inadequate, increase the footing depth (h) and repeat the calculations.

- Design Reinforcement: Calculate the required area of steel reinforcement (As) and select appropriate bar size and spacing.

- Check Development Length: Verify adequate development length for both column dowels and footing reinforcement.

- Check Bearing Stress: Verify bearing stress at the column-footing interface. Design dowels if needed.

- Settlement Review: Review the settlement analysis from the geotechnical report.

- Detailing: Prepare detailed reinforcement drawings following code requirements.

Software & Tools:

- Structural Analysis Software: ETABS, SAFE, RISAFoundation (for obtaining column loads and potentially for footing analysis).

- Spreadsheet Software: Excellent for performing iterative calculations for footing depth, reinforcement design, and shear checks. Create your own!

- Hand Calculations: Essential for validating software results and understanding the design principles.

Common Mistakes to Avoid:

- Inaccurate Load Determination: Critical! Incorrect loads lead to undersized/oversized footings.

- Overlooking Geotechnical Report: The SBC is the foundation of the design.

- Inadequate Shear Design: Punching shear is a common failure mode.

- Insufficient Development Length: Leads to bond failure.

- Ignoring Code Requirements: Safety depends on code compliance.

- Poor Detailing: Improper bar placement can significantly reduce capacity.

Recommended Reading:

- “Reinforced Concrete: Mechanics and Design” by James K. Wight. Still a top recommendation. Focus on the chapters covering footings and detailing.

- “Design of Reinforced Concrete Structures” by Jack C. McCormac and Russell H. Brown. Another excellent textbook covering the fundamental principles of reinforced concrete design, including detailed sections on foundation design.

- ACI 318 “Building Code Requirements for Structural Concrete” Essential – Obtain the latest version and familiarize yourself with the relevant sections on foundations.

Conclusion:

RCC column footing design is a fundamental skill for structural engineers. By following a systematic approach, carefully considering all relevant factors, and utilizing appropriate tools, you can design safe, durable, and cost-effective foundations. Always remember to consult the latest building codes and guidelines, and don’t hesitate to seek guidance from experienced engineers or geotechnical specialists when needed. Good luck with your designs!